🔥 HiTHIUM Completes World’s First Open-Door Fire Test on 5MWh DC block

🔥 HiTHIUM Completes World’s First Open-Door Fire Test on 5MWh DC block

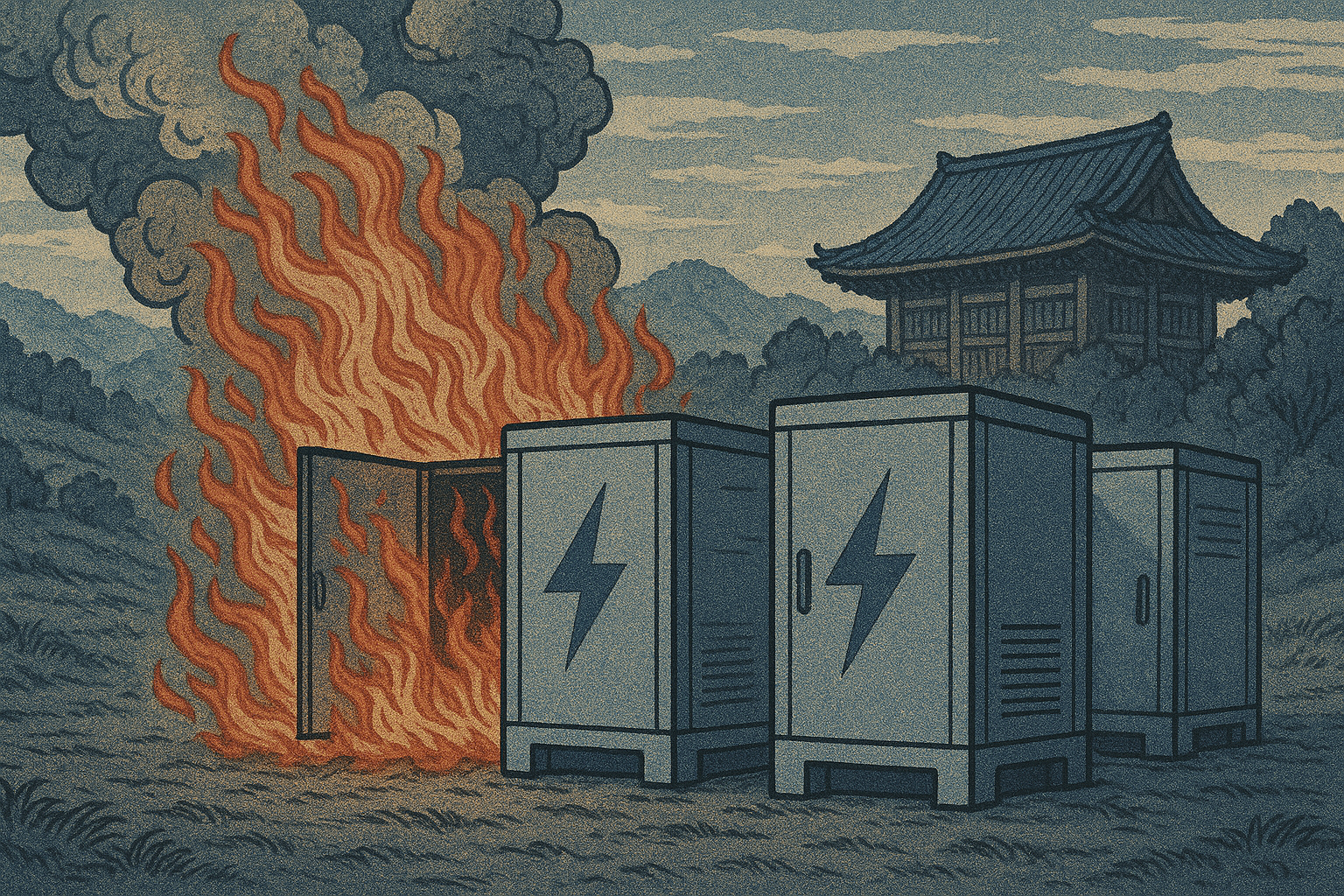

On June 5, 2025, HiTHIUM successfully completed what it claims to be the first-ever all open-door large-scale fire test of its 5 MWh DC Block in Xiamen, China. Conducted by UL Solutions and observed by US fire protection engineers, the system endured 15 hours of open-door combustion under UL 9540A and NFPA 855 standards without thermal propagation to adjacent units, demonstrating robust passive safety performance.

The container doors remained fully open throughout the test

The container doors remained fully open throughout the test

Technical Highlights

- Test performed on 5 MWh DC Block with all doors left open, creating an unrestrained, oxygen-rich combustion environment.

- 15 cm spacing side-by-side and back-to-back between battery containers.

- Conducted at 100 % state of charge (SOC) to stress-test the system under maximum thermal energy conditions.

- Fire suppression systems were deactivated, relying solely on passive fire protection design.

- Carried out by UL Solutions and witnessed by certified US fire protection engineers; adhered to UL 9540A and NFPA855 safety standards.

- After 15 hours of full combustion with flames exceeded 1,300 °C, the structure remained intact with no thermal propagation to adjacent containers.

BESStology Perspective

- Fire Containment Cuts Land Costs: Given that adjacent DC blocks no longer require wide separation, developers can use land more efficiently, lowering acquisition or lease costs and thereby improving BESS economics.

- Higher Standards Limit Competition: Stricter fire safety tests demand major investments for DC and AC Block manufacturers, favoring large players with resources and limiting competition from smaller companies.

This post is licensed under CC BY 4.0 by the author.